Oils and Fats have their own characteristics smell, flavour durability and stability and react differently when frying.

Direct packing of oils as they exit the refinery eliminate some of these factors and hence they perform at their peak offering the customer economy and performance.

Some helpful suggestions for best results and performance on oils:

Handling

loss of performance can be attributed to the various forms of extra handling and exposure to the ”Elements” from storage to shipping and even transport.

Light

store away from direct light and cover when not being used.

Contamination

Avoid risk of contamination and rancidity mixing new and old oils, can decrease performance and longevity when Frying

Temperature

Store and receive your oils at ambient temperature.

Oxygen

avoid excessive use of oxygenation, often occurs when filtering for long periods.

Simple things to a help you protect the longevity and performance of your oil

- Avoid direct sunlight.

- Avoid detergents.

- Avoid copper and brass utensils.

- Avoid excessive moisture.

- Avoid salt in the oil.

- Allow for oil expansion in the fryer when bringing oil to frying temperature.

- Store and deliver oil containers at ambient temperature.

- Check and maintain fry temperatures regularly.

- Check thermostats on fryers are calibrated regularly.

- Fryer is clean from contamination before adding oil.

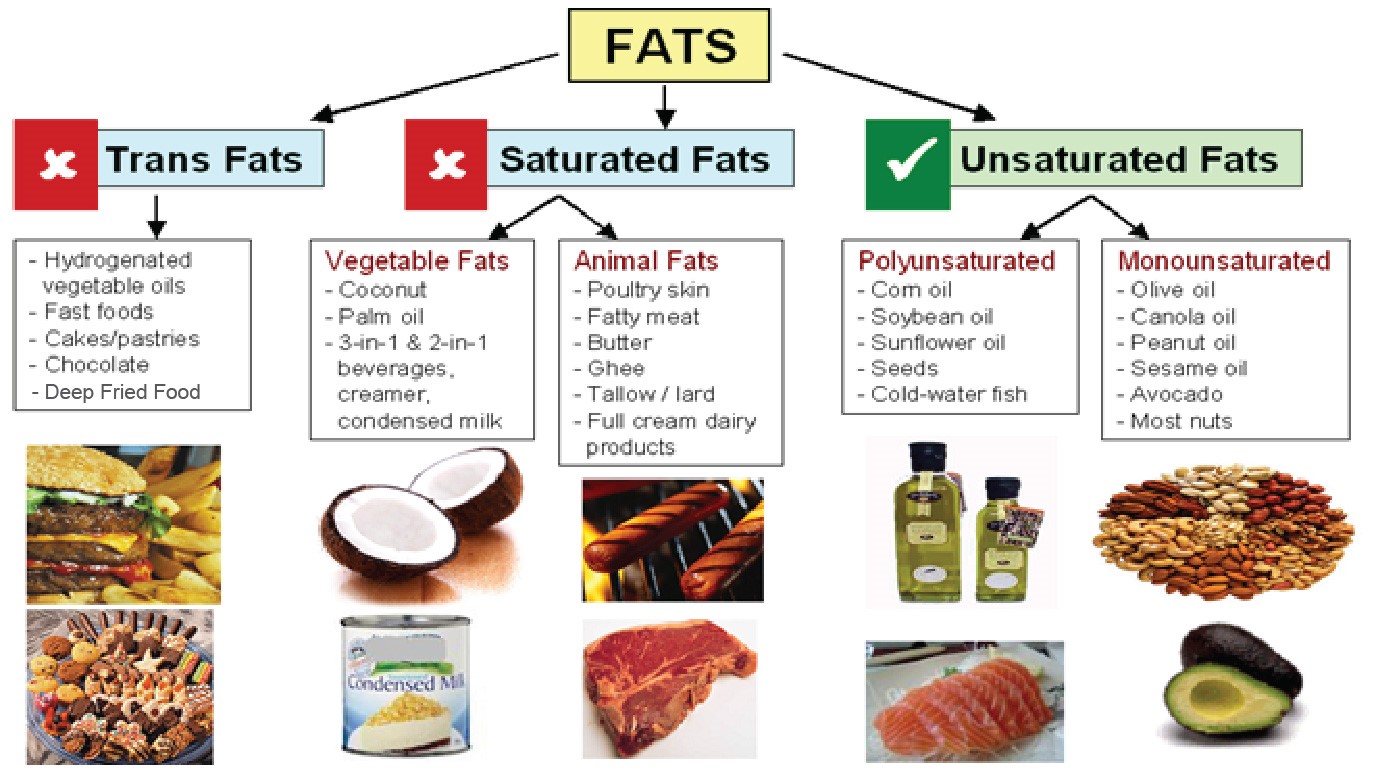

GOOD FATS VS BAD FATS

GOOD FATS

MONOUNSATURATED FATS (OMEGA-9)

Monounsaturated fats are liquid at room temperature and naturally occur in many foods.

POLYUNSATURATED FATS (OMEGA-3)

Polyunsaturated fats also are liquid at room temperature and naturally occur in many foods.

BAD FATS

TRANS FATS

Most trans fats are artificially produced as a result of partial hydrogenation, which is a process used to convert liquid oil to a solid.

SATURATED FATS

Saturated fats are typically solid at room temperature and naturally occur in foods such as meat.